Dec 30, 2025

As national security concerns mount and energy storage demand accelerates, NextNRG'spartnership with A123 Systems addresses a critical supply chain vulnerability

A revealing investigation published by The New York Times has exposed a strategic vulnerability affecting both the Pentagon and America's AI industry: heavy dependence on Chinese battery technology.

The Numbers Tell the Story

China manufactured 99 percent of the world's lithium iron phosphate (LFP) battery cells in 2024 and controls more than 90 percent of main components, according to International Energy Agency data cited by the Times. For U.S. military forces, this translates to reliance on Chinese supply chains for approximately 6,000 individual battery components across weapons programs.

"There are foreign parts in 100 percent of our weapon systems and military platforms," Tara Murphy Dougherty, Govini's chief executive, told defense officials.

Two Critical Vulnerabilities

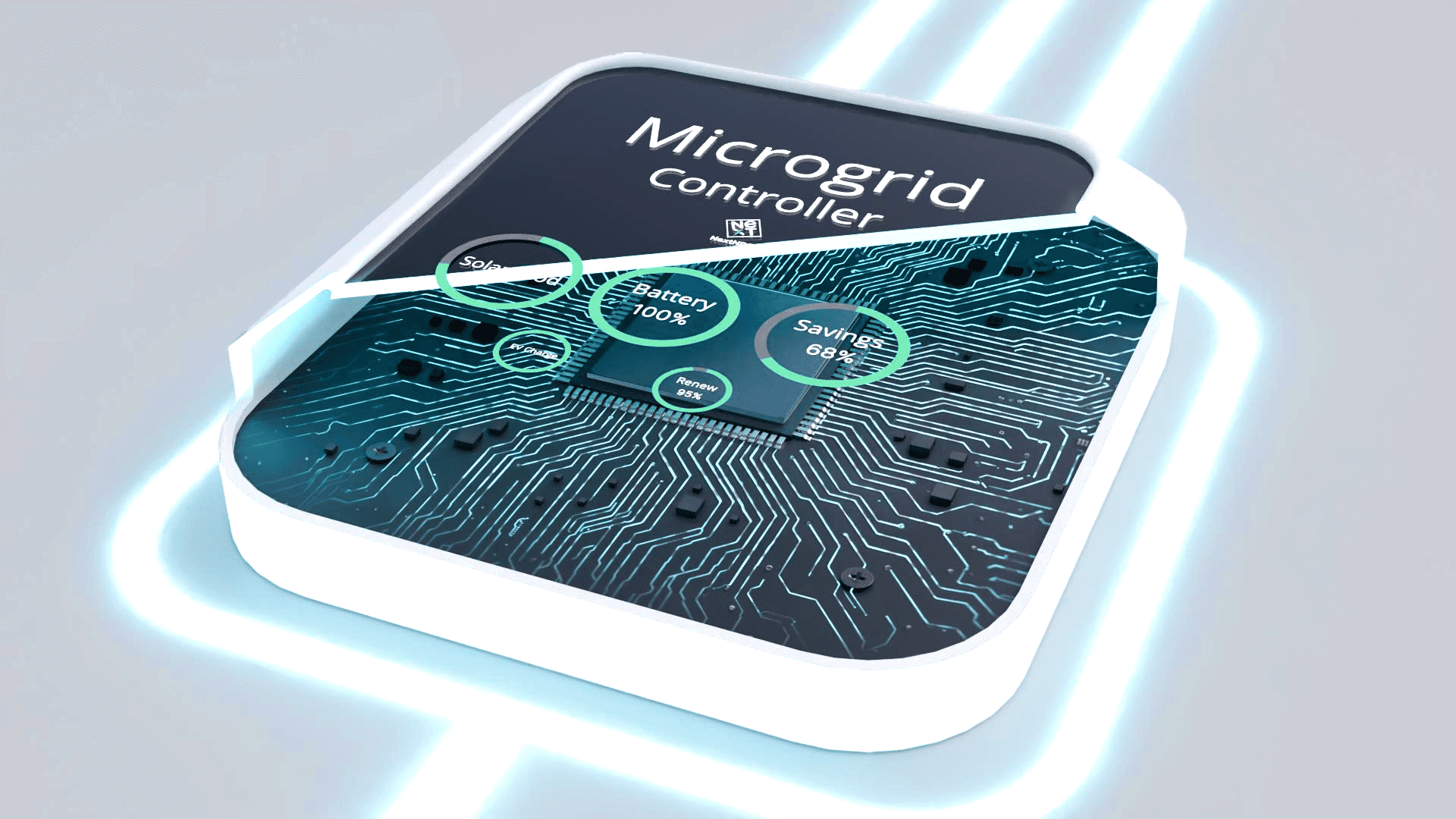

AI Infrastructure: Data centers powering America's AI industry require massive battery systems for 99.999 percent uptime reliability. Google has installed more than 100 million battery cells across its data centers, while Microsoft aims to eliminate diesel backup generators by 2030. An AI query requires approximately 10 times the electricity of traditional internet searches, and even minor power disruptions can cause "silent data corruption" that compromises AI models.

Military Applications: Modern warfare runs on batteries, from drones to night vision goggles, lasers to satellites. The average soldier carries 25 pounds of batteries on a standard patrol. Lessons from Ukraine demonstrate the critical nature of battery supply chains, where Chinese export restrictions have slowed production and tripled prices for drone components.

Policy Shifts Direction

The Trump administration has recognized batteries as essential for AI and national security. The National Defense Authorization Act now includes Pentagon restrictions on battery purchases from "foreign entities of concern," primarily China. The Energy Department has allowed Biden-era grants for battery manufacturers to proceed and announced up to $500 million for battery materials projects.

"They're recognizing that China's stranglehold on the battery supply chain is undermining our national security," said Samm Gillard, executive director of the Battery Advocacy for Technology Transformation Coalition.

A Strategic Evolution Toward U.S. Manufacturing

As global battery supply chains recalibrate, industry leaders are increasingly focused on pairing proven, high-performance battery technology with future U.S. manufacturing. One promising path is the localization of advanced battery chemistries through domestic production—an approach that reflects how global technology leaders have historically adapted to shifting trade and industrial policy environments.

In this context, A123 Systems brings a distinct advantage: deep expertise in patented advanced LFP battery technology and the capability to support future U.S. manufacturing development. While domestic production is not yet in place, A123 is laying the groundwork for U.S.-based capacity over time.

Looking ahead, the establishment of U.S. manufacturing would offer meaningful benefits:

• Lower system costs over time, driven by tariff avoidance and streamlined logistics

• Stronger alignment with U.S. industrial and energy policy, supporting domestic jobs and infrastructure

• Improved supply chain resilience, with greater control over sourcing and deployment

Importantly, this model does not require NextNRG to finance manufacturing expansion. Manufacturing development is expected to be supported by third-party capital and strategic investment aligned with U.S. industrial priorities. This allows NextNRG to remain capital-efficient while positioning itself to deploy domestically produced systems as they come online.

The Path Forward

The announced Memorandum of Understanding between NextNRG and A123 Systems directly addresses these supply chain vulnerabilities by establishing a framework to evaluate U.S.-based manufacturing development together, while immediately advancing deployment across NextNRG’s growing U.S. project portfolio.

“A123’s proven technology and manufacturing capabilities align perfectly with our mission to deploy intelligent, resilient energy systems nationwide,” said Michael D. Farkas, Executive Chairman and CEO of NextNRG. “As battery storage demand accelerates across healthcare, commercial, and utility sectors, this agreement positions us to secure reliable access to premium storage solutions built in America, for America.”

Under the MOU, the parties will prioritize the future use of domestically manufactured systems as they become available—supporting tariff avoidance, mitigating geopolitical exposure, and aligning with federal and state preferences for U.S.-based energy infrastructure.

Analysts estimate it could take at least half a decade for U.S. manufacturers to produce enough LFP cells to meet domestic demand. Achieving that scale will require coordinated partnerships between technology providers, developers, manufacturers, and capital partners.

“When we think about the future of manufacturing and defense, and how we should be protecting critical supply chains, the chips are the brain, and batteries are the heart,” said Elaine K. Dezenski, an expert on geopolitical risk at the Foundation for Defense of Democracies.

The collaboration between NextNRG and A123 Systems reflects the type of long-term, capital-efficient partnership needed to strengthen America’s battery supply chain. As the executive director of the International Energy Agency has warned, reliance on a single country for strategic commodities “is always risky.”

The question is no longer whether the United States needs a robust domestic battery industry—it’s how quickly and effectively that industry can be built.

For more information about NextNRG's energy storage solutions and domestic manufacturing partnerships, visit www.nextnrg.com

Sources:

● "The Pentagon and A.I. Giants Have a Weakness. Both Need China's Batteries, Badly." The New York Times, December 23, 2025. Hiroko Tabuchi, Brad Plumer, and Harry Stevens.

● NextNRG, Inc. Press Release: "NextNRG and A123 Systems LLC Sign MOU to Advance U.S. Battery Energy Storage Projects," December xx, 2025.

Don’t Miss Out

Join our newsletter to get latest insights for your brand growth!