Feb 20, 2026

Cold storage facilities operate under strict thermal limits. A few hours of lost power can destroy inventory worth millions. Food safety, pharmaceutical integrity, and contractual penalties are all tied to uptime. Storms and grid failures expose the weakness of traditional backup systems. Diesel generators start slowly. Fuel logistics become uncertain. Manual switching introduces risk. Static battery schedules fail to align with actual load behavior. A modern microgrid changes this risk profile.

NextNRG brings together four critical layers for cold storage resilience: advanced forecasting, intelligent microgrid control, inverter reliability, and battery state management.

First, forecasting.

Cold storage load is not constant. Compressor cycles, defrost schedules, dock activity, and ambient temperature all influence demand. RENCAST forecasting models short interval load patterns and weather impacts. This allows operators to anticipate peak draw and pre-position storage. During an approaching storm, the system can ensure batteries are fully prepared before grid instability occurs.

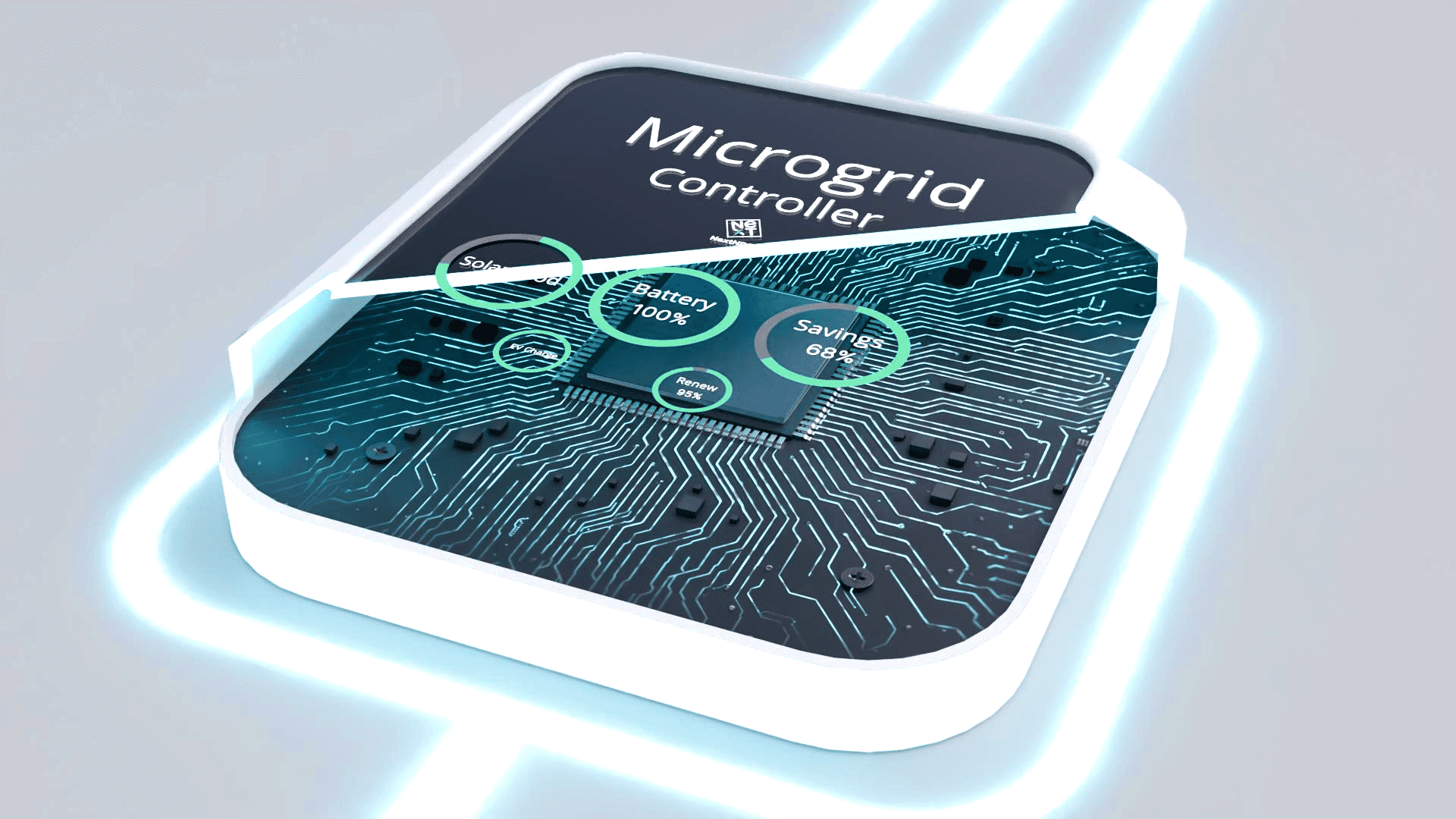

Second, intelligent microgrid control.

The patented microgrid controller coordinates solar, batteries, and backup generation in real time. When grid voltage drops or frequency deviates, the system isolates automatically using grid forming inverter logic. There is no waiting for manual intervention. Critical refrigeration circuits remain powered. Non-essential loads can be temporarily reduced to extend runtime.

The controller also optimizes daily economics. Batteries charge during low price windows and discharge during high demand periods. This reduces demand charges and operating cost while preserving capacity for resilience events.

We examine this financial impact in more detail in our analysis of battery storage economics.

Third, inverter reliability.

Solar generation and battery storage depend on power electronics. The inverter is the component that converts DC energy into usable AC power for facility loads. In cold storage operations, inverter reliability directly affects uptime.

Voltage instability, harmonic distortion, thermal stress, and component fatigue can all reduce inverter performance over time. During severe weather events, electrical stress increases. A microgrid is only as resilient as its power conversion layer.

High reliability inverter design, fault tolerance, and thermal management reduce the probability of unexpected shutdowns. Advanced grid forming capabilities also allow the system to maintain voltage and frequency stability during islanding events. This ensures that refrigeration compressors and sensitive control systems continue operating without disruption.

In high value facilities, inverter performance is not a secondary detail. It is foundational to system reliability.

Fourth, battery state of charge and state of health management.

Batteries degrade if misused. Cold storage facilities require predictable runtime during outages. The system continuously monitors state of charge and state of health. It avoids deep cycling that would shorten battery life. It reserves a resilience buffer, so the facility maintains guaranteed runtime if the grid fails unexpectedly.

Modeled impact for a 200,000 square foot cold storage facility

Assumptions:

• Peak load of 4.5 megawatts

• Annual electricity cost of 3.2 million dollars

• Inventory value exceeding 50 million dollars

• Average outage exposure of 6 hours per year

Modeled results with intelligent microgrid:

• Peak demand reduction of 15 to 20 percent

• Annual demand charge savings of approximately 250,000 dollars

• Energy optimization savings of 80,000 to 120,000 dollars

• Generator runtime reduced by about 40 percent

• Outage related product loss reduced by over 70 percent

• Battery lifespan extended through optimized cycling strategy

Operational advantage

• Automatic islanding during storms

• Continuous refrigeration during blackouts

• Stable voltage and frequency control during grid disturbances

• Improved compliance with food and pharma standards

• Reduced insurance and spoilage risk

• Better tenant confidence in multi-tenant facilities

Cold storage facilities cannot tolerate uncertainty. They require precision and reliability. Intelligent forecasting anticipates demand. Real time control ensures seamless transition during grid events. Robust inverter performance stabilizes power delivery. Battery health logic protects long term performance.

This combination turns a cold storage warehouse into a resilient energy asset. It reduces operating cost while protecting high value inventory. In an industry where downtime equals loss, intelligent microgrids provide measurable protection.

Don’t Miss Out

Join our newsletter to get latest insights for your brand growth!