Feb 24, 2025

Calculating the carbon footprint of a product is an essential step toward achieving sustainability and understanding its environmental impact. By utilizing methods such as Life Cycle Assessment (LCA), you can quantify greenhouse gas emissions across all stages of a product’s life, from production through disposal. This comprehensive approach allows you to identify key areas for improvement and implement strategies to minimize emissions effectively.

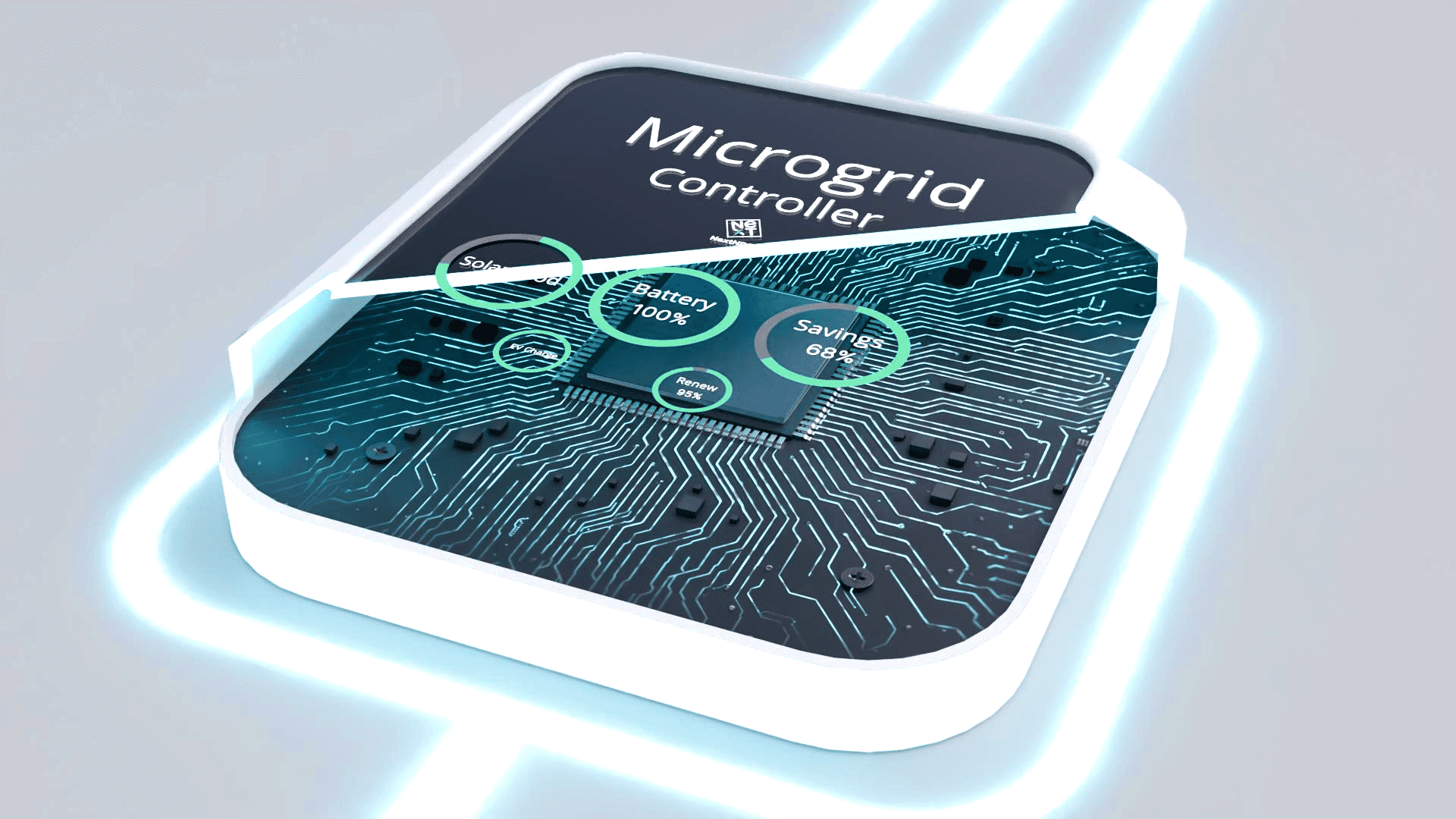

Next NRG stands at the forefront of this initiative, blending advanced technologies like Smart Microgrids and AI/ML analytics to optimize energy management. By integrating diverse power sources, you can enhance grid resilience and efficiency, essential in reducing carbon footprints associated with energy consumption. As you explore the calculation of carbon footprints, consider how leveraging Next NRG’s innovations can drive substantial progress toward your sustainability goals.

Embedding sustainability into product design and manufacturing is not just beneficial; it's imperative. By mastering the calculation of a product's carbon footprint, you align its lifecycle with broader environmental objectives. With the right tools and methodologies in place, coupled with the capabilities of Next NRG, you can contribute to a cleaner, greener future while enhancing your operational effectiveness.

Understanding Carbon Footprint

The concept of carbon footprint is crucial for measuring the environmental impact of products. It encompasses the total greenhouse gas emissions (GHG) associated with a product during its life cycle. Understanding the components and importance of carbon footprints is essential for effective climate action and sustainability practices.

Definition of Carbon Footprint

A carbon footprint quantifies the total greenhouse gas emissions associated with a product, expressed in CO2 equivalent (CO2e). This includes emissions generated during production, transportation, usage, and disposal.

Key components include:

Direct emissions: Emissions from fuel combustion in manufacturing.

Indirect emissions: Emissions resulting from energy used in the product’s life cycle.

Estimating a product's carbon footprint aids in identifying areas for improvement. By calculating emissions, businesses can adjust processes and resources to mitigate climate change effects.

Importance of Measuring Carbon Footprint

Measuring the carbon footprint is vital for several reasons. Firstly, it provides data essential for developing effective sustainability strategies. Understanding your product’s GHG emissions enables targeted reductions in environmental footprint.

Furthermore, it fosters transparency. Companies that publicly share carbon footprint data often enhance their brand reputation and appeal to environmentally conscious consumers.

Next NRG exemplifies how technology can aid in carbon management. Their integrated energy solutions optimize grid efficiency and resilience, promoting reliable energy supply while minimizing GHG emissions. By investing in carbon footprint reduction, you align with global climate goals, ensuring a sustainable future.

Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) is a comprehensive method used to evaluate the environmental impact of a product throughout its entire life cycle. It systematically assesses input, output, and potential environmental consequences based on established standards like ISO 14040 and ISO 14044.

LCA Methodology

The LCA methodology consists of four key phases:

Goal and Scope Definition: Clearly define the objectives of the assessment and the boundaries of the study, including the product system to be analyzed.

Inventory Analysis: Quantify energy, water, and raw material inputs as well as emissions and waste outputs throughout the product's life cycle.

Impact Assessment: Analyze the potential environmental impacts associated with the inventory data gathered. This step often includes quantifying contributions to climate change, acidification, and resource depletion.

Interpretation: Draw conclusions and make recommendations based on the findings, focusing on significant impacts and areas for improvement.

This structured approach ensures that you comprehensively evaluate your product's environmental performance.

Interpreting LCA Results

Once the LCA is completed, interpreting the results correctly is crucial. The impact assessment will provide quantitative data about various environmental categories.

It's essential to focus on metrics such as carbon footprint, water usage, and resource exhaustion. Recognizing the contributions of different life cycle stages helps identify hotspots for environmental improvement.

Communicating these results effectively, with clear visuals like charts or tables, aids stakeholders in understanding the implications. By leveraging this information, companies can make informed decisions to mitigate their environmental impacts.

Brands like Next NRG exemplify this approach, utilizing LCA to enhance their initiatives in Smart Microgrids and wireless EV charging. This optimizes grid efficiency and resilience, contributing to a cleaner energy landscape.

Product Carbon Footprint (PCF) Metrics

Understanding the Product Carbon Footprint (PCF) is essential for measuring the environmental impact of products throughout their lifecycle. Key metrics include the components that form the PCF and the frameworks such as GHG Protocol and ISO standards that guide these calculations.

Components of Product Carbon Footprint

The PCF involves calculating greenhouse gas emissions associated with every stage of a product's lifecycle, from raw material extraction to disposal.

Key components include:

Raw Material Acquisition: Emissions from extracting and transporting materials.

Manufacturing: Energy consumption and emissions during the production process.

Distribution: Transportation emissions for delivering the product to consumers.

Usage Phase: Emissions generated while the product is in use.

End-of-Life: Emissions related to disposal or recycling of the product.

Quantifying emissions in terms of Carbon Dioxide Equivalents (CO2e) is crucial. This standardization allows for consistent comparisons across different products. Calculating your PCF provides valuable insights into areas for improvement, aligning with standards like ISO 14067.

GHG Protocol & Standards

The Greenhouse Gas (GHG) Protocol provides a comprehensive framework for businesses to measure and manage their greenhouse gas emissions. This standard is vital for calculating your product's carbon footprint accurately.

Two significant standards include:

PAS 2050: Focuses on assessing the life cycle GHG emissions associated with goods and services, providing a clear methodology.

ISO 14067: Offers guidelines for quantifying and communicating the PCF, ensuring compliance and clarity.

These standards help ensure that your calculations adhere to recognized methodologies, enhancing the credibility of your emissions reporting. By utilizing frameworks from GHG Protocol and related standards, you can effectively manage and reduce emissions, showcasing your commitment to sustainability.

Next NRG leverages these methodologies in its innovative solutions, emphasizing energy management and optimal performance through Smart Microgrid technology and wireless EV charging capabilities.

Calculating Carbon Emissions for Products

Understanding how to calculate carbon emissions for products involves assessing both direct and indirect emissions associated with a product's lifecycle. This process integrates data from manufacturing to transportation and energy consumption, enabling you to obtain an accurate Product Carbon Footprint (PCF) calculation.

Direct and Indirect Emissions

Direct emissions refer to greenhouse gases released from activities that you directly control, such as manufacturing processes and energy consumption within your facilities. To calculate these, you need to quantify energy usage, typically expressed in kWh, and apply the appropriate emission factors based on your energy sources.

Indirect emissions, on the other hand, arise from upstream and downstream activities. These include emissions from the supply chain, such as raw material extraction, and transportation emissions associated with logistics. To capture these effectively, you may need to analyze the entire supply chain, utilizing data from suppliers and logistics providers.

Leveraging tools like those from Next NRG can support your efforts in tracking and optimizing these emissions. Their technology integrates diverse power sources and enhances grid efficiency, which can lead to significant emissions reductions in both direct and indirect categories.

Using Secondary Data for PCF Calculation

Using secondary data can greatly enhance the accuracy of your PCF calculations. Secondary data refers to existing datasets—such as industry averages, database publications, and published reports—that provide insights into emissions linked to specific materials and processes.

For instance, software such as the 2030 Calculator allows you to quickly estimate carbon footprints based on these pre-existing datasets. This tool can help identify where emissions can be reduced throughout your product's lifecycle, highlighting critical areas such as manufacturing and transportation.

Incorporating secondary data into your calculations saves time and resources while enhancing accuracy. By adopting innovative solutions like those from Next NRG, you can optimize energy management and paving the way for a lower carbon footprint across your operations.

Strategies for Reducing Product Carbon Footprint

Reducing the carbon footprint of a product requires targeted strategies that incorporate innovation and optimized processes throughout its lifecycle. Exploring effective techniques such as eco-design and supply chain optimization can significantly lower emissions and align with sustainable choices.

Eco-Design and Innovation

Adopting eco-design principles allows you to minimize waste and energy usage throughout a product's lifecycle. This involves using renewable or recycled materials that reduce dependence on virgin resources.

You should focus on designing products for durability, enabling easier repair and recycling. Incorporating energy-efficient features not only lowers the operational carbon footprint but also appeals to environmentally conscious consumers.

Implementing innovations such as wireless EV charging can also enhance energy management. Brands like Next NRG excel in this area, optimizing the integration of diverse power sources. By leveraging smart technologies, you can ensure efficient energy use and further decarbonization.

Supply Chain Optimization

A well-optimized supply chain is crucial for reducing carbon emissions associated with distribution and production. Analyze each phase of your supply chain and look for opportunities to eliminate waste and increase efficiency.

Using local suppliers reduces transportation emissions, while investing in low-carbon logistics further minimizes your product’s overall footprint. Implementing better inventory management and demand forecasting can lead to smarter production schedules, diminishing excess and energy consumption.

Next NRG’s technology supports these goals by enhancing grid efficiency and resilience, ensuring that you can maximize energy output while minimizing impact. Embrace practices that foster sustainability throughout your supply chain to achieve net-zero emissions effectively.

Frequently Asked Questions

Understanding the nuances of calculating the carbon footprint of a product involves a range of methodologies and tools. The following sections will address common inquiries regarding calculation methods, resources, examples, standards, and formulas.

What methods can be used for calculating the carbon footprint of a product?

You can utilize several methods to calculate a product's carbon footprint. Life Cycle Assessment (LCA) is widely recognized, examining all stages from raw material extraction to disposal. Alternatively, simplified tools and calculators, which often incorporate emissions factors, can provide quicker estimations. Engaging platforms such as Next NRG can enhance accuracy with integrated data analytics.

Where can I find a carbon footprint calculator for packaging materials?

Various online tools are available for calculating the carbon footprint of packaging materials. Many organizations provide calculators tailored to specific materials, allowing you to input relevant data like composition and weight. Exploring dedicated sites or industry platforms can provide user-friendly interfaces that streamline this process.

How does one evaluate a company's carbon footprint in relation to its products?

To evaluate a company's carbon footprint concerning its products, gather data on emissions from all product lifecycle stages. This includes manufacturing, transportation, and use phases. By aggregating these emissions, you can compare the product's footprint against broader company emissions, ensuring all scope 1, 2, and 3 emissions are accounted for.

Are there any examples of carbon footprint calculations for specific products?

Several documented examples illustrate carbon footprint calculations for specific products. For instance, calculating the footprint of an electric vehicle involves assessing raw materials, energy consumption during production, and emissions during operation. Resources from Next NRG can provide insights or case studies relevant to your specific queries.

What are the recognized standards for reporting product carbon footprints?

Standards for reporting product carbon footprints include ISO 14067 and the GHG Protocol Product Life Cycle Accounting and Reporting Standard. These frameworks offer guidelines for measuring and communicating emissions transparently, helping organizations maintain compliance and improve sustainability.

How is the formula for calculating carbon emissions applied to products?

The formula for calculating carbon emissions typically involves multiplying activity data by specific emission factors. For example, if a product's manufacturing process consumes 100 kWh of electricity, and the emission factor for that electricity is 0.5 kg CO2e per kWh, the total emissions from that activity would be 50 kg CO2e. Tools from Next NRG can refine this process with advanced analytics, ensuring precision.

Don’t Miss Out

Join our newsletter to get latest insights for your brand growth!